If You Can Make It, We Can Measure It

At Acro Tech Centre, we provide Gujarat’s most advanced precision inspection ecosystem — powered by large-format CMMs, portable metrology systems and expert engineers. Every inspection delivers certified accuracy, trusted by manufacturers across Engineering, CNC, Auto, Aviation, Oil & Gas and Heavy Metals.

CMM MEGA – Large-Format Precision Inspection

Measuring Range: 1200 x 2000 x 1000 mm

Accuracy: ±2.2 + (L/350) μm

Ideal For: Large components, heavy manufacturing, tooling, moulds, castings.

Capabilities

- Micron-level dimensional inspection

- First article inspection (FAI)

- Multi-axis complex geometry measurement

- Casting / Forging validation

- GD&T-based inspection and reporting

Deliverables

- Fully certified CMM report

- GD&T deviation map

- Colour 3D deviation plot

- PDF + raw CMM files

CMM SPECTRA – High-Accuracy Industrial CMM

Measuring Range: 700 x 1000 x 600 mm

Accuracy: ±1.8 + (L/350) μm

Ideal For: Precision machining, high-tolerance components, R&D, QC labs.

Capabilities

- High-accuracy dimensional testing

- Repeatability testingRepeatability testing

- Small–medium high-precision parts

- GD&T validation

Deliverables

- Precision CMM report

- Profile analysis

- GD&T summarised report

On-Site CMM | FARO Portable 3D Measurement arm

Model: Faro 3.5m 7 Axis

Accuracy: 0.045mm (0.0018 inches ±2.2 + (L/350) μm

Ideal For: High-mix low-volume components, shop-floor inspection, large parts that cannot be moved.

Capabilities

- 3D scanning

- On-site inspection

- Feature measurement

- Tooling, fixtures, and machine validation

- Comparative analysis with CAD

Deliverables

- FARO inspection report

- 3D scan data (STL)

- Fit-to-CAD colour map

VMM 300 S – Non-Contact Vision Measuring System

Precision Inspection for Delicate & Complex 2D Profiles.

Parts that are too soft, too small, or too intricate for a touch-probe. The VMM 300 S uses high-resolution optical vision to measure 2D geometry with micron-level accuracy. Perfect for rubber seals, gaskets, electronic PCBs and plastic micro-components where "touching" the part introduces error.

Measuring Range: 300 x200 x 200 mm

Accuracy: (2.7 + L/250) Microns (High Precision)

Sensor: 1.3 MP High-Resolution Telecentric Camera

Capabilities

- Profile & Surface Illumination (8-Zone LED)

- Geometric measurement of radii, chamfers, and holes

- Batch inspection of small parts

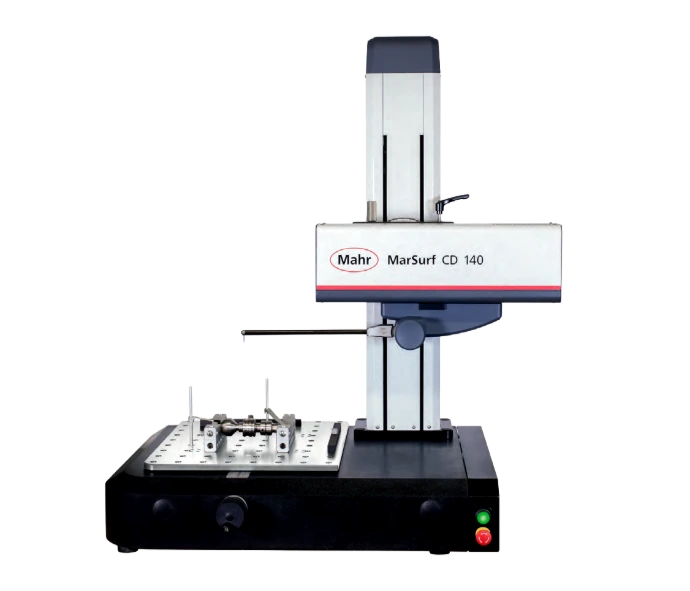

MarSurf CD 140 – High-Precision Contour Testing

When a standard CMM probe is too large to fit. The Mahr CD 140 utilizes a diamond-tipped stylus to physically trace and graph the exact contour of threads, undercuts, and deep grooves. We don't just "estimate" your thread profile; we plot it with nanometer resolution.

Scanning Range: 140 mm (X-Axis) x 70 mm (Z-Axis)

Accuracy: 0.045mm (0.0018 inches ±2.2 + (L/350) μm

Resolution : 19 nanometers (Ultra-Precision)

Probing Force : 4 mN to 30 mN (Adjustable for soft metals)

Probing Force : 4 mN to 30 mN (Adjustable for soft metals)

Capabilities

- Thread Root & Pitch Analysis

- Roughness Measurement (Optional capability)

- Unknown Contour Scanning (Scan-to-CAD for 2D profiles)

- Tooling, fixtures, and machine validation

- Comparative analysis with CAD